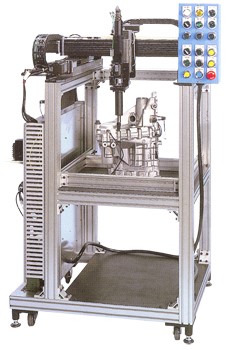

DDK electric tightening machine

The main features of the AFC-1500 electric tightening machine are:

1. Lightweight and affordable

◆ Small size and low cost

The controller adopts digital technology, greatly reducing the structure of various components in the past; Control the operating system to be lightweight and reduce overall costs. In response to the different needs of tightening various screws, on the basis of universal hardware, performance modes and software selection are used to achieve the purpose of use while reducing the investment of users in using this product.

◆ No wiring required

Equipped with multiple communication interfaces and control modes, eliminating numerous wiring operations; Implement fully networked systems (DEVICE-NET, INTER-BUS, PROFIBUS, CC-LINK, and others)

2. Visibility

◆ Screen operation

Equipped with a portable operator in the field of mechatronics, it can easily set the system's status, tighten parameters, analyze result data, and store and process data through Windows programs. By utilizing the request for help function, assistance can be provided to the operator. Based on usage requirements, a fixed or portable computer or monitor can be selected, which is also beneficial for reducing costs.

3. High quality

◆ Pursuing the company's own quality

The heart part of the tightening structure is a torque sensor, which always adheres to the principle of quality first from design to manufacturing, and can also provide users with product quality tracking certificates. The system can also be equipped with a tightening shaft ID (calibration torque, model recognition and other quality management intelligent intelligence) to prevent the occurrence of defective products caused by human factors, including setting errors. Provide quality and service life assurance for tightening tools based on ISO5393. Having a separate service system; According to the needs of users, we can quickly provide regular maintenance, renovation, repair and other after-sales services.

Provide tightening solutions in the assembly field according to customer usage requirements.

Application examples:

◆ In line: suitable for automatic online tightening, design, and manufacturing of various equipment requirements, as well as mobile (handheld).

◆ Automatic supply type (automatic part feeder): The bolt tightening device is combined with the bolt automatic supply device to achieve full automation of bolt tightening. Can automatically supply various screws and nuts.

◆ Robot style: Emphasizing versatility and equipped with the screw tightening technology of the robot arm, it can achieve automatic screw feeding. The robotic arm can be a straight or multi axis type.

◆ Rocker arm type (Rocker arm installation: manual operation): The flexible rocker arm is a balanced structure, which can greatly reduce the operator's labor intensity. The tightening accuracy of the bolt tightening machine can also be guaranteed, so high-precision screw tightening can be carried out. Standard equipped with anti leakage function.